What Is 1000 Denier Cordura?

1000 denier Cordura is a high-performance fabric known for its exceptional strength, abrasion resistance, and durability. It is widely used in military gear, outdoor equipment, and motorcycle apparel due to its rugged nature and longevity. This material offers superior resistance to tears and wear, making it a preferred choice for demanding applications.

Cordura is a brand of durable synthetic fabrics originally developed by DuPont and now produced by Invista. It is made from high-tenacity nylon fibers, woven tightly to create a strong, wear-resistant material. The term “1000 denier” refers to the fiber thickness of the fabric, with a higher denier count indicating a heavier and tougher material. 1000D Cordura fabric is engineered to endure extreme stress while maintaining flexibility and performance.

Composition and Manufacturing Process

1000 denier Cordura is primarily made from nylon 6,6 fibers, known for their strength and resilience. The manufacturing process involves:

- Weaving: The nylon fibers are woven into a dense structure to increase durability.

- Coating: A polyurethane or PVC coating is applied to enhance water resistance and improve the fabric’s lifespan.

- Dyeing and Finishing: The fabric undergoes a treatment process that enhances color retention, UV resistance, and overall performance.

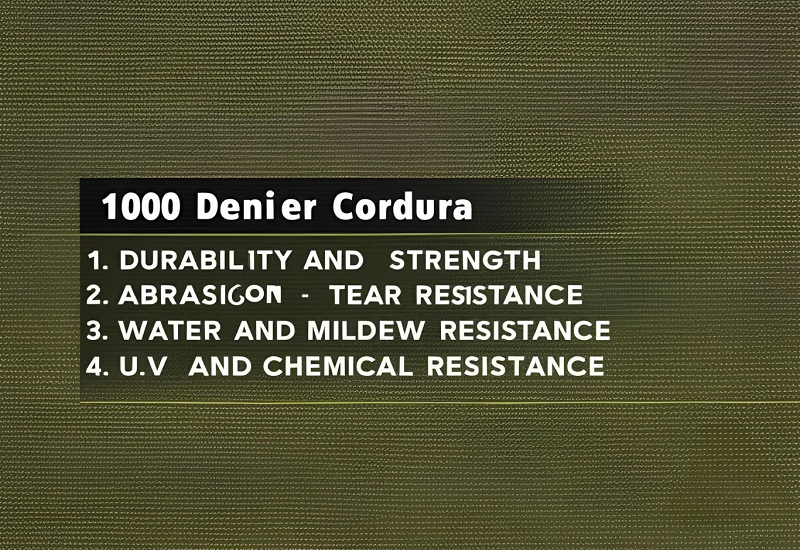

Key Properties of 1000 Denier Cordura

1. Durability and Strength

1000 denier Cordura is highly resistant to wear and tear, making it ideal for heavy-duty applications. Its high tensile strength ensures long-lasting performance in extreme conditions. Unlike regular nylon, this material does not degrade quickly, even with continuous exposure to rough environments.

2. Abrasion and Tear Resistance

Compared to other synthetic fabrics, 1000D Cordura offers superior abrasion resistance, which is why it is used in gear exposed to rough surfaces. Independent tests show that Cordura fabrics last several times longer than standard nylon or polyester when subjected to friction and mechanical stress.

3. Water and Mildew Resistance

The fabric’s polyurethane or PVC coating provides water resistance, preventing moisture absorption. While not fully waterproof, it repels light rain and splashes effectively. It also resists mildew growth, making it ideal for humid environments where other materials might deteriorate.

4. UV and Chemical Resistance

1000 denier Cordura is treated to resist UV damage, ensuring it maintains its color and integrity when exposed to sunlight. It also has a certain level of resistance to chemicals, oils, and fuels, which is beneficial in industrial and military applications.

Common Uses of 1000 Denier Cordura

1. Military and Tactical Gear

Used in backpacks, pouches, vests, and boots, where durability is crucial for long-term field use. Many tactical vests, plate carriers, and heavy-duty military bags are made with 1000D Cordura due to its ability to withstand combat conditions and heavy loads.

2. Outdoor and Adventure Equipment

Found in backpacks, tents, and luggage, ensuring gear can withstand tough conditions. High-end hiking and camping gear manufacturers use 1000D Cordura because of its ability to endure rough terrain, frequent movement, and extreme weather.

3. Motorcycle Apparel

Incorporated into jackets, gloves, and pants for abrasion resistance and rider protection. Many professional-grade motorcycle gear brands reinforce high-impact areas with 1000D Cordura to protect riders in case of falls or accidents.

4. Workwear and Heavy-Duty Clothing

Used in construction clothing, tactical uniforms, and outdoor workwear. Industries that demand rugged performance, such as oil and gas or forestry, rely on 1000D Cordura for protective outer layers that resist punctures and mechanical wear.

Comparison: 1000D Cordura vs. Other Fabrics

1. 500D vs. 1000D Cordura

- 500D Cordura: Lighter, more flexible, and used in applications where weight matters. Often found in lightweight tactical gear and bags where flexibility is needed.

- 1000D Cordura: Heavier, stronger, and preferred for extreme durability. It is the go-to choice for military and industrial-grade equipment that must endure high stress.

2. Cordura vs. Other Synthetic Fabrics

- Cordura vs. Polyester: Cordura is stronger and more abrasion-resistant. Polyester is less durable but lighter and more cost-effective.

- Cordura vs. Standard Nylon: Cordura lasts longer and performs better in rugged environments, while standard nylon is more flexible but less resistant to wear.

Advantages and Considerations

Benefits of 1000D Cordura

- Exceptional durability and longevity—lasts much longer than regular nylon or polyester.

- Superior resistance to abrasions and tears, making it ideal for high-impact applications.

- Water and mildew resistance for extended usability in wet conditions.

- UV and chemical resistance for added protection in extreme environments.

- Versatile applications across multiple industries, from military to outdoor gear.

Potential Drawbacks

- Heavier than lower denier fabrics, which may not be ideal for lightweight applications.

- More expensive compared to standard nylon or polyester materials.

- Can be stiff, making it less flexible for certain product designs.

- Not fully waterproof, requiring additional treatments or liners for complete water protection.

Conclusion

1000 denier Cordura is a superior fabric known for its strength, durability, and resistance to abrasions and water. Its widespread use in military, outdoor, and protective gear highlights its reliability. Whether for tactical gear, motorcycle apparel, or industrial applications, 1000D Cordura remains one of the best materials available for extreme durability and performance. When selecting a material that must withstand tough conditions, this fabric is a top choice for professionals worldwide.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.