Twill weave is a fundamental textile pattern characterized by its distinctive diagonal ribbing. This structure is achieved by passing the weft thread over one or more warp threads and then under two or more warp threads, creating a ‘step’ between rows that results in the diagonal pattern. The advantages of twill weave include enhanced durability, wrinkle resistance, superior drape, and the ability to conceal stains. These advantages of twill weave make it a highly versatile choice for various applications. As a result, the advantages of twill weave contribute to its widespread use in apparel, upholstery, and industrial textiles, offering both strength and flexibility in textile manufacturing.

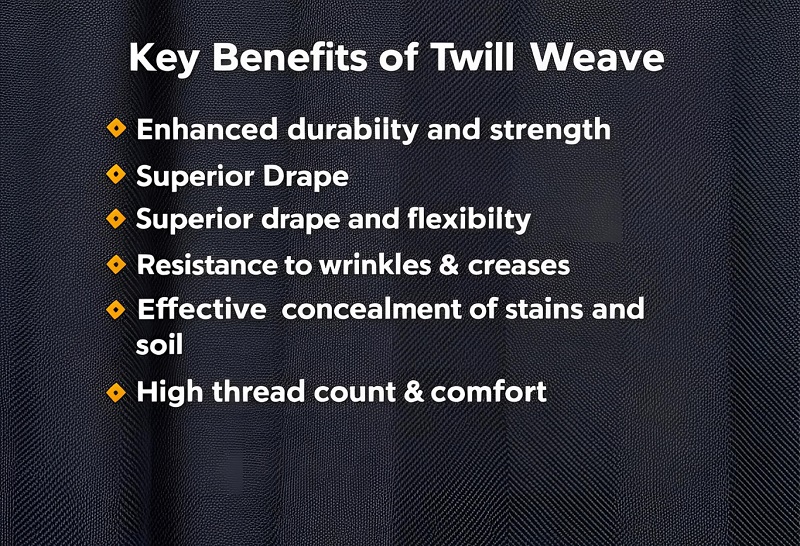

Key Benefits of Twill Weave

Enhanced Durability and Strength

The diagonal structure of twill weave contributes significantly to the fabric’s strength and durability. This pattern allows for a higher thread count, resulting in a dense and robust material that can withstand substantial wear and tear. Fabrics like denim and gabardine exemplify this durability, making them ideal for heavy-use items such as jeans and workwear.

Superior Drape and Flexibility

Twill fabrics are known for their excellent draping qualities. The weave’s structure imparts a soft and flexible nature to the fabric, allowing it to conform gracefully to shapes and movements. This makes twill particularly suitable for garments that require a fluid and elegant appearance, such as tailored suits and flowing skirts.

Resistance to Wrinkles and Creases

One of the notable advantages of twill weave is its inherent resistance to wrinkles and creases. The diagonal lines in the weave help the fabric maintain a smooth appearance, reducing the need for frequent ironing and enhancing the overall aesthetic appeal. This property is especially beneficial for clothing items like pants and jackets, as well as home textiles such as curtains and upholstery.

Effective Concealment of Stains and Soil

The texture and pattern of twill weave fabrics make them adept at concealing stains and soil. The uneven surface created by the diagonal ribs helps mask imperfections, making twill an excellent choice for items prone to frequent use and exposure to dirt, such as work uniforms and furniture coverings.

High Thread Count and Comfort

Twill weave allows for a higher thread count, resulting in fabrics that are not only durable but also soft and comfortable against the skin. This combination of strength and comfort makes twill fabrics ideal for bedding and intimate apparel, providing a luxurious feel without compromising on longevity.

Practical Applications of Twill Weave Fabrics

Apparel Industry

In the apparel sector, twill weave fabrics are widely used to produce durable and stylish clothing. Items such as jeans, chinos, and suits benefit from twill’s strength and drape, offering both comfort and a polished appearance. The fabric’s resistance to wrinkles and stains further enhances its suitability for everyday wear.

Home Furnishings

Twill weave’s durability and aesthetic appeal make it a popular choice for home furnishings. Upholstery fabrics, curtains, and bedding crafted from twill offer longevity and maintain their appearance over time, even with regular use. The fabric’s ability to resist wrinkles and conceal stains contributes to its practicality in household settings.

Industrial and Workwear

Due to its robust nature, twill weave is extensively used in industrial applications and workwear. Uniforms, overalls, and protective clothing made from twill provide the necessary strength to endure harsh working conditions while ensuring comfort for the wearer. The fabric’s resistance to wear and tear makes it a reliable choice for demanding environments.

Conclusion

The advantages of twill weave in textiles are manifold, encompassing enhanced durability, superior drape, wrinkle resistance, effective stain concealment, and a comfortable feel due to high thread counts. These attributes make twill an invaluable choice across various applications, from fashion and home décor to industrial uses. As a textile engineer with extensive experience in fabric manufacturing, I recognize the enduring value of twill weave fabrics in meeting both functional and aesthetic demands in the textile industry.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.