Elongated Twill Weave in Textile Manufacturing

Elongated twill weave is a specialized variation of twill weave, designed to create distinct diagonal lines that differ from the standard 45-degree angle. This modification enhances the fabric’s durability, drape, and appearance, making it suitable for various textile applications. It is widely used in denim, upholstery, and industrial fabrics due to its improved structural integrity and unique aesthetic properties.

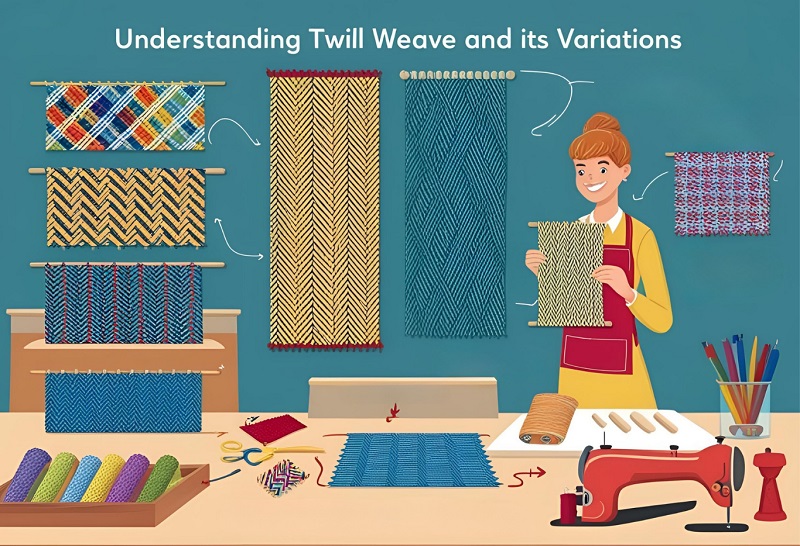

Understanding Twill Weave and Its Variations

What Is Twill Weave?

Twill weave is a fundamental weaving technique where the weft thread passes over and under multiple warp threads in a staggered pattern, forming diagonal ribs. Compared to plain weave, twill fabrics offer better drape, abrasion resistance, and flexibility. Twill weaves are known for their distinct diagonal ridges, which can be manipulated to create different patterns and effects in textiles.

Types of Twill Weave

Twill weave is classified into:

- Warp-Faced Twill: More warp threads appear on the fabric’s surface, making it more durable and resistant to wear.

- Weft-Faced Twill: The weft threads are more prominent on the fabric’s surface, giving a softer feel and higher flexibility.

- Balanced Twill: Warp and weft threads are evenly distributed, creating a uniform fabric texture.

Twill weaves can also include special variations like herringbone, broken twill, and diamond twill, each offering unique visual and functional properties.

What Is Elongated Twill Weave?

Structure and Characteristics

Elongated twill weave differs from regular twill by modifying the twill angle. Instead of the standard 45-degree diagonal, the twill lines in this weave are either steeper (closer to vertical) or flatter (closer to horizontal). This is achieved by adjusting the step number—the rate at which the interlacing points shift. By altering this structure, manufacturers can create fabrics with specific draping qualities and mechanical strengths tailored for different applications.

How Elongated Twill Is Formed

- Warp-Way Elongated Twill: Created by advancing warp interlacings over multiple weft threads, producing a steep diagonal. This technique increases fabric stiffness and strength, making it suitable for durable applications.

- Weft-Way Elongated Twill: Formed when weft interlacings extend over several warp threads, generating a flatter diagonal. This structure enhances fabric flexibility and softness, making it ideal for apparel and home textiles.

Elongated twill weave is designed to achieve specific performance characteristics, including enhanced resistance to tearing, increased visual appeal, and better dimensional stability.

Manufacturing Techniques for Elongated Twill Weave

Drafting and Peg Plan

A straight draft is commonly used for elongated twill, with careful planning of the peg plan to achieve the desired twill angle. The number of harnesses required depends on the weave complexity. The peg plan dictates the exact points where warp and weft interlace, ensuring the fabric maintains a consistent and predictable pattern.

Adjusting Twill Angles

Twill angles are altered by:

- Changing the ratio of warp to weft interlacings.

- Selecting an appropriate step number for advancing interlacements.

- Modifying warp and weft densities to control the fabric’s appearance and texture.

Adjusting these parameters allows textile engineers to fine-tune the mechanical properties of the fabric, optimizing it for specific end uses such as workwear, technical textiles, and fashion fabrics.

Applications and Benefits of Elongated Twill Weave

Textile Products Utilizing Elongated Twill

Elongated twill weave is used in:

- Denim and Apparel Fabrics: Provides better drape, durability, and wrinkle resistance, making it a preferred choice for high-end denim and workwear.

- Upholstery and Home Textiles: Enhances aesthetic appeal and resistance to wear, making it ideal for sofas, curtains, and decorative fabrics.

- Industrial Fabrics: Offers strength for technical applications, such as conveyor belts, protective clothing, and reinforced materials.

This weave’s versatility allows manufacturers to develop specialized fabrics that meet the demands of various industries.

Advantages Over Other Twill Weaves

- Increased durability due to tighter interlacings, reducing fabric distortion over time.

- Unique diagonal texture for decorative appeal, offering a refined look in apparel and home textiles.

- Enhanced fabric flexibility for better comfort and usability, making it an excellent choice for fashion and upholstery applications.

- Improved resistance to mechanical wear and tear, ensuring a longer lifespan for finished textile products.

Conclusion

Elongated twill weave is a versatile textile structure that enhances both functionality and aesthetics. Its ability to modify twill angles makes it a valuable choice for various fabric applications, from fashion to industrial use. Understanding its structure and manufacturing techniques helps textile engineers create high-quality woven fabrics tailored to specific requirements. With its durability, flexibility, and unique visual appeal, elongated twill weave continues to be a significant component in the textile industry.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.