Weaves play a significant role in determining the properties and appearance of fabrics. Understanding the difference between plain weave twill weave satin weave can help you choose the right material for your projects, whether for fashion, upholstery, or industrial use. In this article, we will break down the unique features, benefits, and typical applications of each weave structure.

What Are Weave Structures?

Weaves are patterns formed by interlacing threads of yarn in a fabric. The arrangement of these threads defines the structure, texture, and strength of the material. By altering the weave, fabric properties like durability, softness, flexibility, and appearance change significantly. The three most common weave types are plain, twill, and satin, each with distinct characteristics that make them suitable for various uses.

Plain Weave: The Foundation of Fabric Structures

Structure and Appearance

Plain weave is the most basic and oldest weaving pattern. It consists of a simple over-and-under pattern, where each weft thread crosses over and under each warp thread. This simple structure results in a fabric that is firm and strong, with a balanced, even appearance. The fabric feels lightweight but durable, and it has a smooth surface with little texture.

Properties and Applications

Plain weave fabrics are highly durable and breathable, making them ideal for everyday wear and common textiles. These include shirts, bed linens, and muslin. The balanced structure gives plain weave fabrics the ability to withstand wear and tear, making them a popular choice in both casual and formal clothing. Despite being durable, plain weave fabrics tend to wrinkle easily and may require ironing for a smooth finish.

Twill Weave: Introducing Diagonal Patterns

Structure and Appearance

Twill weave is distinguished by its diagonal pattern, created by the weft thread passing over and under multiple warp threads in a staggered manner. This results in a diagonal line that runs across the fabric, giving it a textured appearance. The most common example of twill is denim, where the distinctive diagonal pattern is clearly visible.

Properties and Applications

Twill fabrics are known for their enhanced durability, making them suitable for heavy-duty clothing such as jeans, jackets, and workwear. The diagonal weave allows the fabric to drape better and adds strength without compromising flexibility. Twill is also more resistant to wrinkles than plain weave fabric, although it can still crease under pressure. Twill weaves are commonly found in fabrics like tweed, gabardine, and chino, where durability and comfort are key.

Satin Weave: Achieving a Lustrous Finish

Structure and Appearance

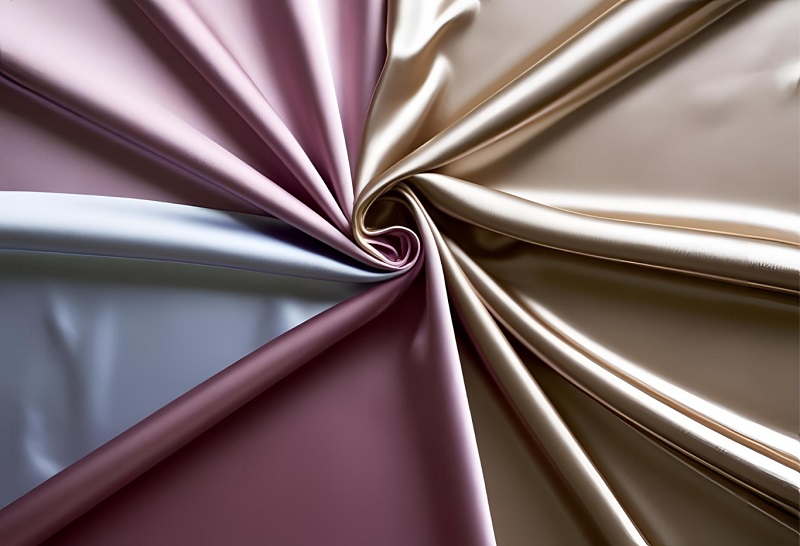

Satin weave features a structure where the warp threads float over several weft threads, creating a smooth surface. The weft threads are usually fewer than the warp threads, allowing the fabric to reflect light and achieve a glossy or shiny finish. This luster is the defining feature of satin weave fabrics, making them look luxurious and polished.

Properties and Applications

Satin fabrics are smooth and soft, providing a rich, glossy surface. They are commonly used in evening wear, bridal gowns, and upholstery for their elegant look. However, satin is less durable compared to plain and twill weaves due to the floating warp threads. These threads are more prone to damage, making satin less suitable for heavy-duty applications. Satin fabrics may also require careful handling to avoid snagging and losing their sheen.

Difference Between Plain Weave Twill Weave Satin Weave

Durability and Maintenance

The difference between plain weave twill weave satin weave becomes clear when comparing their strength and durability. Plain weave fabrics are the most durable of the three, with a tightly interwoven structure that makes them resistant to tearing and abrasion. Twill weave is also quite strong, especially in heavier fabrics like denim. However, satin weave is more delicate due to the floating threads, making it more susceptible to damage. Satin fabrics require more careful handling and are less durable over time compared to plain and twill weaves.

Aesthetic Appeal

In terms of appearance, satin weave stands out with its glossy, reflective surface, offering a sophisticated and luxurious look. Twill weave has a distinctive texture with its diagonal pattern, often associated with rugged or formal styles. Plain weave, while functional and strong, tends to be plain in appearance, making it less visually striking compared to twill and satin.

Cost and Accessibility

Plain weave is the most affordable to produce due to its simple structure. Twill and satin weaves, on the other hand, require more intricate techniques and thus tend to be more expensive. However, the cost difference can be worth it depending on the desired properties and aesthetic appeal of the fabric.

Choosing the Right Weave for Your Needs

When choosing between plain weave, twill weave, and satin weave, consider the fabric’s intended use. If you need something durable and easy to maintain, plain weave is the best choice. For more flexibility, comfort, and a textured appearance, twill weave is ideal. Satin weave is the go-to option for high-end, glossy fabrics but may not be suitable for everyday wear due to its delicacy.

Understanding the difference between plain weave twill weave satin weave ensures that you make an informed decision when selecting fabrics for your projects. Each weave type offers unique benefits, and selecting the right one depends on factors like durability, aesthetic appeal, and maintenance requirements.

Conclusion

Choosing the right fabric weave can significantly impact the success of your project, whether you’re designing clothing, upholstery, or other textile products. The difference between plain weave twill weave satin weave lies in their structure, durability, and appearance. Each type has unique advantages that make them suitable for different applications. Knowing the difference between plain weave twill weave satin weave helps you match the fabric to your functional and visual needs. By recognizing the difference between plain weave twill weave satin weave, you can make more informed choices for better results in fabric selection.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.