What is Interlock Jersey Fabric?

As a textile engineer, I often recommend interlock jersey fabric for garments that require softness, structure, and stretch. This double-knit fabric is thicker than regular single jersey and offers excellent durability. It is widely used in T-shirts, leggings, babywear, and activewear due to its smooth texture and strong hold. In this article, we’ll explore the structure, features, and common uses of interlock jersey fabric.

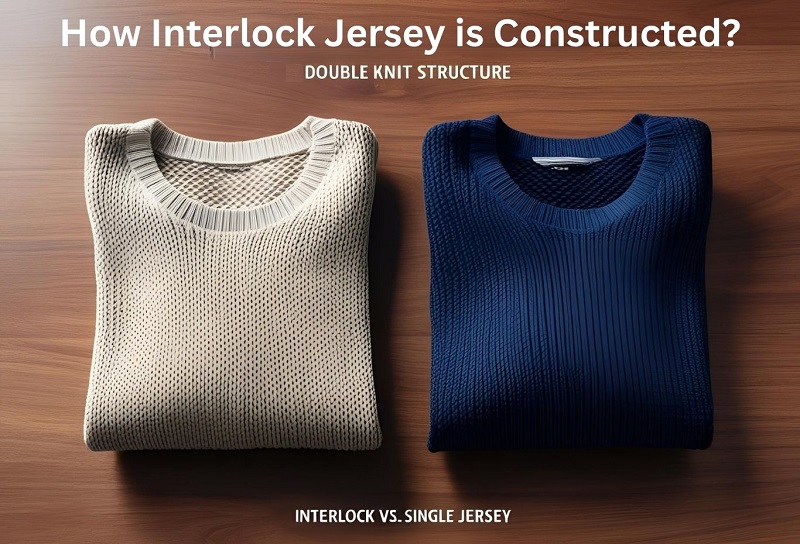

How Interlock Jersey is Constructed

Double Knit Structure

Interlock jersey fabric is made using two needle beds on a knitting machine. The front and back stitches are interlocked, forming a dense and stable fabric. This method gives the fabric a uniform look on both sides, unlike single jersey, which has a clear front and back.

Interlock vs. Single Jersey

The main difference lies in the structure. Interlock is thicker, less transparent, and has less curl at the edges. It stretches well in both directions, while single jersey stretches more in one. This makes interlock knit fabric more stable and easier to handle during sewing.

Key Properties of Interlock Jersey Fabric

Thickness and Stretch

Interlock is thicker than standard jersey, but still breathable. It has a firm stretch, offering flexibility without losing shape. The double-knit design adds strength while maintaining softness.

Softness and Comfort

Interlock jersey fabric feels smooth on both sides. It is gentle on the skin and causes less irritation. This makes it a good choice for clothing worn close to the body, such as underwear and baby clothes.

Skin-Friendly Material

Since it is usually made from cotton or cotton blends, interlock jersey is hypoallergenic and suitable for people with sensitive skin. It absorbs moisture well and allows airflow, reducing sweat buildup.

Common Uses of Interlock Jersey Fabric

Clothing Applications

This fabric is popular in casual and athletic clothing. It holds shape well and stretches comfortably, making it ideal for:

- T-shirts

- Polo shirts

- Baby bodysuits

- Activewear

- Lightweight sweatshirts

Benefits for Manufacturers

For garment producers, interlock knit fabric offers a balance of ease and quality. It resists fraying, is easy to sew, and keeps its shape during cutting and stitching. Its durability also means fewer returns or complaints from customers.

Care Instructions for Interlock Jersey Fabric

Washing and Drying Tips

To maintain fabric quality, use cold or warm water during washing. Avoid hot water as it may cause shrinkage. Use mild detergent and set the machine to a gentle cycle.

Maintaining Shape and Softness

Tumble dry on low heat or air dry when possible. Avoid over-drying, as it can reduce softness. Iron on low settings if needed, but often the fabric doesn’t wrinkle much due to its knit structure.

Interlock Jersey vs Other Knit Fabrics

Interlock vs Rib Knit

Rib knit has more texture and higher elasticity. It’s often used for cuffs, neckbands, and trim. Interlock jersey fabric is smoother, less elastic, but better at holding shape for full garments.

Interlock vs Double and Single Jersey

- Single jersey is lightweight and flexible but can curl at the edges.

- Double jersey is thicker but may lack the softness of interlock.

- Interlock combines the best of both: softness, thickness, and stability.

Why Choose Interlock Jersey Fabric?

Ideal for Sensitive Skin and Everyday Wear

As a professional in textile manufacturing, I often recommend interlock jersey fabric for everyday clothing. Its smooth surface and moisture-absorbing quality make it ideal for both children and adults.

Reliable Fabric for Various Needs

Whether you’re making babywear, sportswear, or daily apparel, interlock jersey fabric delivers comfort and strength. Its stability during production also reduces waste and simplifies cutting and stitching.

Final Thoughts

Interlock jersey fabric is a practical choice for clothing that needs to be soft, breathable, and strong. It offers a better structure than single jersey and a smoother feel than rib knits. Whether you’re a manufacturer or buyer, knowing the benefits of this fabric helps you make better choices for long-lasting garments.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.