Types of Dobby Weave in Textile Manufacturing

Dobby weave is a structured weaving method used to create small, geometric patterns on fabric. The dobby loom controls warp yarns individually or in small groups, allowing for detailed surface textures. These weaves are popular in both fashion and interior textiles due to their clean structure, unique feel, and practical strength.

As a textile engineer with experience in industrial weaving setups, I can say dobby weave remains one of the most versatile constructions in fabric design. It works well across natural and synthetic fibers and offers flexibility in function and finish.

What Is a Dobby Weave?

The dobby weave is produced using a dobby loom. This loom enables more control over warp yarn movement than plain or twill looms. As a result, manufacturers can create repeating patterns like squares, stripes, dots, and small florals directly into the weave.

Unlike printed patterns, dobby textures are woven, which increases the fabric’s durability. Depending on the fiber content, dobby weave fabric may be crisp or soft, with patterns that can be subtle or pronounced.

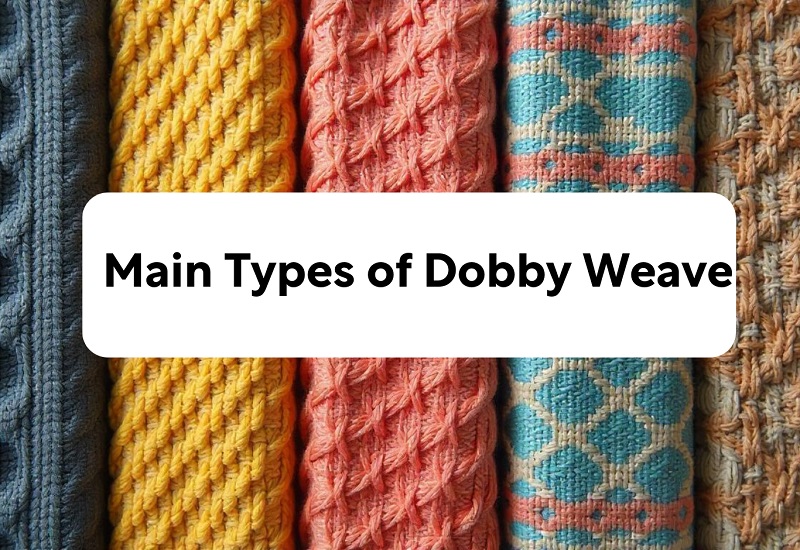

Main Types of Dobby Weave

Each dobby weave pattern serves a purpose. Some are chosen for comfort in apparel, while others are ideal for strong and decorative home textiles. Here are the main types of dobby weave used in textile production:

Rib Check Dobby

Rib check dobby uses alternating yarn tension to create a raised line or rib effect in both directions. This pattern forms small square textures and is common in shirting fabrics, especially cotton-polyester blends. It adds grip and strength to the fabric.

Used in: Formal shirts, office wear, table linens

Fiber types: Cotton, polyester, viscose blends

Small Dot Dobby

This weave creates tiny raised dots across the fabric surface. The dots are formed by lifting selected warp yarns for short intervals during the weave cycle. The result is a clean, minimal look with tactile texture.

Used in: Summer dresses, children’s clothes, soft furnishings

Fiber types: Cotton, rayon, silk

Geometric Dobby

Geometric dobby includes lines, angles, diamonds, and grid-like structures. These patterns give a structured appearance and work well for modern fashion and decor.

Used in: Bags, upholstery, contemporary fashion

Fiber types: Polyester, cotton, jacquard blends

Floral Dobby

Floral dobby features stylized floral or leafy motifs created by selective warp and weft interaction. These fabrics add softness and detail without requiring printing.

Used in: Curtains, dresses, home décor

Fiber types: Cotton, silk, poly-cotton

Textured Dobby

This type of dobby weave focuses on texture instead of shape. Irregular weaves create rough or bumpy surfaces. It’s often found in natural-fiber fabrics for rustic or artisanal looks.

Used in: Cushion covers, tunics, casual wear

Fiber types: Linen, cotton, hemp

Dobby Loom Variations That Affect Weave Types

The dobby mechanism itself affects the type of dobby weave that can be created. There are two main mechanical distinctions:

Single-Lift and Double-Lift Dobby

- Single-lift dobby: Moves one heald frame at a time. Suitable for basic and medium-complexity designs.

- Double-lift dobby: Moves two frames in tandem or in sequence. Allows more variation in pattern.

Positive and Negative Dobby

- Positive dobby: Controls both upward and downward movement of warp threads. Works well for medium to heavy fabrics like upholstery or bags.

- Negative dobby: Lifts threads using springs or counterweights. Mostly used for lighter, soft fabrics.

Common Applications of Dobby Weaves

The types of dobby weave directly affect where the fabric is used. Here are common applications based on function:

Apparel Fabrics

Dobby weave fabrics are often used in dress shirts, blouses, skirts, and trousers. The small patterns add visual interest without bulk. Rib check and small dot types are most common in clothing.

Popular features: Breathability, texture, structure

Home Textiles

In home furnishings, dobby weaves appear in drapes, cushions, duvets, and upholstery. Floral and geometric patterns suit many décor themes. The woven structure holds shape and resists pilling.

Popular features: Durable finish, clean look, easy maintenance

Functional Accessories

Dobby fabric is used in tote bags, laptop sleeves, and scarves. The structure adds strength, and the patterns offer subtle styling without prints.

Popular features: Strength, design clarity, low stretch

Why Dobby Weave Is Still in Demand

Dobby weave fabrics offer clear production advantages. They are:

- Cost-effective: Patterns are built into the weave, saving printing costs.

- Customizable: Design adjustments are easy by reprogramming the dobby loom.

- Durable: Patterns do not fade or wear out like printed fabrics.

The types of dobby weave available today help balance function, visual appeal, and performance—key requirements in both fashion and interiors.

Final Thoughts

Dobby weaving is one of the most practical fabric structures used in textile manufacturing. From simple ribs to detailed floral motifs, the types of dobby weave cover a wide range of functions and looks. Their stability and design flexibility make dobby fabrics a reliable choice for brands, manufacturers, and consumers alike.

Whether you are choosing fabric for shirts, home décor, or accessories, knowing the pattern type helps you select the right material. Rib, dot, floral, geometric, or textured—each type of dobby weave serves a clear purpose.

Manager – Fabric Technical and Sourcing/Product Development/ Sustainable Material Management.

I am a B.Sc .-educated Manager of Fabric Sourcing and Technology with extensive experience in the apparel and fashion industry. Passionate about trend analysis, fabric sourcing, and sustainable textile solutions, I thrive in fast-paced environments that demand innovation, adaptability, and leadership.

As a servant leader, I am committed to honesty, transparency, and continuous process improvement. My expertise spans fabric development, product quality management, and supply chain optimization, ensuring exceptional performance across all facets of sourcing and production.

Core Skills & Expertise

✔ Fabric Sourcing & Development – Specialized in regular and sustainable textiles (BCI, Organic, Recycled).✔ Trend Analysis – In-depth understanding of global fashion and fabric trends.✔ Product Development – Expertise in material innovation and process optimization.✔ Quality Management – Strong focus on process control, ensuring high-quality production.✔ Leadership & Problem-Solving – Solution-oriented approach to team management and decision-making.

Technical Proficiency

🖥 Software & Tools:▪ Microsoft Outlook, Excel, Word▪ PLM (Product Lifecycle Management)

🌱 Sustainable & Ethical Practices:▪ Better Cotton Initiative (BCI)▪ Organic & Recycled Fabric Management

Key Strengths

✅ Solution-Focused Leadership – Driving innovation and efficiency in fabric sourcing.✅ Quick Decision-Maker – Adapting to market shifts and production challenges.✅ Team Player with a Positive Attitude – Ensuring collaboration and productivity.✅ Strong Time Management – Meeting deadlines while maintaining quality.

Professional Achievements

🏆 Li & Fung GEM Award – Recognized for fabric sourcing and supply chain management excellence.🏆 Group CEO GEM Award – Honored for outstanding leadership and process innovation.